How does the Air/Fuel Ratio setup of your burners affect your operation?

Combustion Efficiency, also known as Percent Available Heat, is a measure of the amount of energy that is used in the process, with the remainder being unused (wasted) as it is vented out the stack.

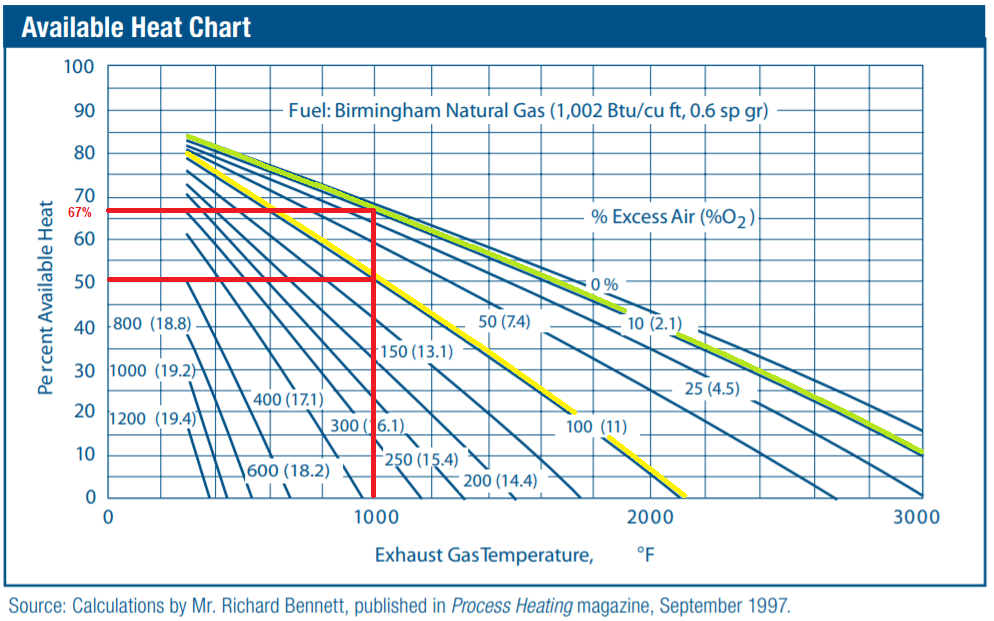

During a recent service visit, #CICPittsburghLLC found burners were set with an Air/Fuel ratio of 100:1. With flue gases typically exhausted at 1000F, the Percent Available Heat is 50% (as read from the chart below). By comparison, the preferred Air/Fuel Ratio is about 11:1. With the same exhaust temperature of 1000F, the chart shows a Percent Available Heat of 67%.

The fuel usage is calculated by dividing the process heat by the Percent Available Heat. For example, if a process consumes 6 MMBtu/hr, then fuel usage with 50% Available Heat is 12 MMBtu/hr. The same fuel usage with 67% Available Heat is 9 MMBtu/hr.

So, by properly setting the Air/Fuel Ratio at the burners, this customer will save 25% on their fuel bill. How much fuel can you save in your operation?