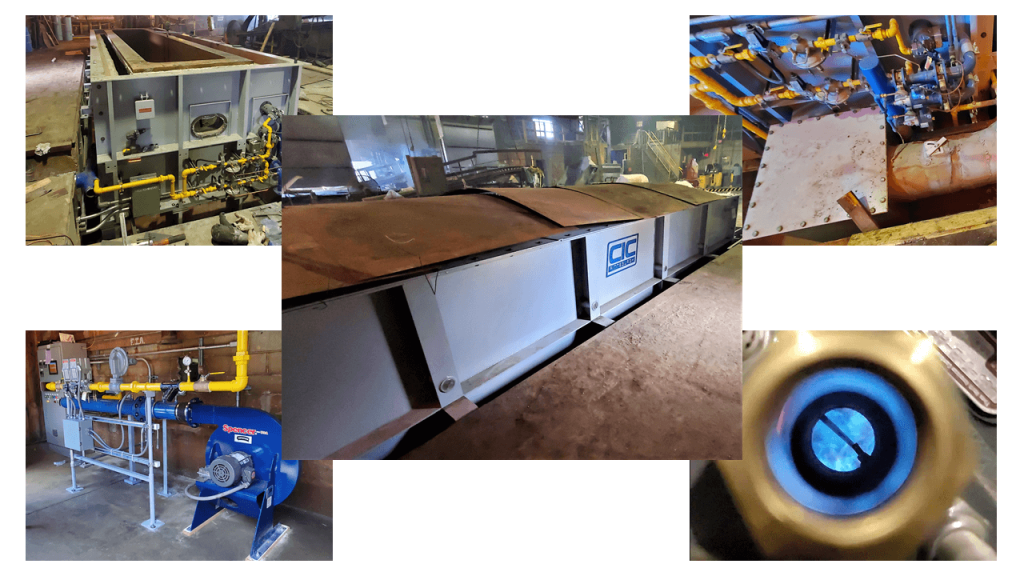

CIC Pittsburgh recently supplied, installed, and commissioned a new Hot Dip Galvanizing Furnace for AZZ’s K1 Galvanizing Line at their Rockford, IL facility. The furnace is designed for a 22’ x 4’ x 5’ kettle. This furnace was installed in an existing pit to replace an old furnace that had reached the end of its useful life. The new furnace is end-fired with four pulse-fired high velocity burners for improved temperature uniformity and extended kettle life. With the new furnace, CIC Pittsburgh provided all new controls for compliance with current standards, improved reliability, and easier operation and maintenance.