As the trend for Galvanizing plants moves towards kettles that are longer, wider, and deeper, the loading on the kettle walls, which is transmitted through the kettle supports and out to the furnace structure, becomes substantially higher. In order to maximize kettle life and plant productivity, furnace designers are challenged to develop suitable structural designs.

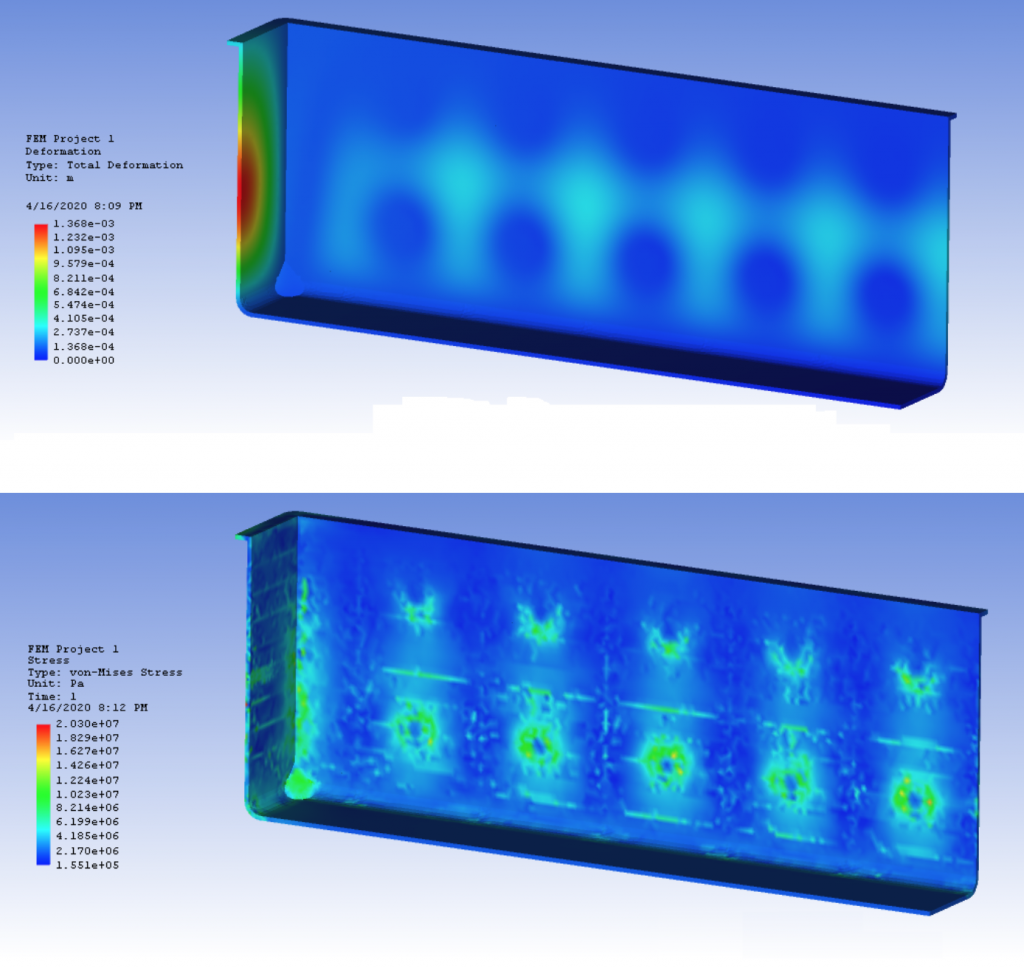

Rather than relying on traditional rules of thumb that are inherently limited in their application, CIC Pittsburgh uses Finite Element Analysis to analyze the wall stresses and deflections, which verifies that the design is optimized for your application.

Be sure to contact CIC Pittsburgh the next time you are considering changing your kettle or installing a new furnace.